PERMANENT POOL SEALING (EXISTING CONSTRUCTION) WITH PENETRON'S INDOCHEMICAL ACTION AND CRYSTAL GROWTH SYSTEM® OR USING CONVENTIONAL SEALCOAT SYSTEMSTM SYSTEMS. Permanent Swimming Pool Waterproofing

Existing concrete pools are considered those that are fully constructed (perhaps already in use), often with landscaped garden or surrounding areas (covered with tiles, wood, marble, etc.) or adjacent to other constructions, such as buildings, basements, garages, tunnels visiting walls, etc. Also, there are unfinished pools, with existing concrete walls or, in some cases, with smoothing cement mortar but not finished with a finished surface (tiles, paints, etc.).

I. Waterproofing of a swimming pool with a finished surface of the concrete surface

- Repair of concrete nests from unwoven parts, as well as sealing of "morels" and "hairpins" with PENETRON abrasive penetrant® and the repair agent of corresponding technology PENECRETE MORTAR® and repair of cracks with running water with PENEPLUG fast setting crystal growth mortar®.

Depending on the working procedures, concrete surface can be treated and cleaned by a high-pressure jet water blasting (300-500 bar), for better visual contact with faulty areas.

Then we treat water ingress from cracks with PENEPLUG active crystal growth quick setting mortar®, (mixed with a little water, form of gravel). To implement PENEPLUG®, we should widen the cracks with a digging tool to a width of 2-3 cm and with a conical base on the inside, for better anchoring of the tachypekt during its application. We deal with the stop joints in the same way, cutting on both sides with a cutting wheel and then creating a conical "gutter", about 3 cm wide, using a digging tool. Then, we apply the PENEPLUG quick-setting mortar®.Permanent Pool Waterproofing

Permanent Pool Sealing

In some cases, depending on the design of the works, we can apply PENEPLUG first®, so as to limit the inflow of water and then to carry out the treatment with water jetting, since the PENEPLUG® has acquired good mechanical strength. It must be clarified that PENEPLUG®, after drawing (still fresh), 1 – 2 coats of PENETRON water-based chemical action and crystal growth mixture should be applied to it®, in a mixing ratio of 5 parts PENETRON powder® with 3 – 3.5 parts of water (by volume), for easy application with a brush, and consumption in total for both 2 layers, approx. 1.5 kg/m2.

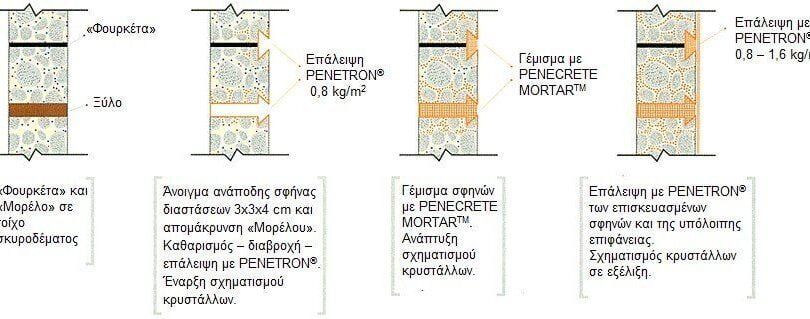

By mechanical means we widen the holes and nests that have resulted from concreting. Also, by mechanical means we widen the area around the "hairpins" to a width of at least 35 mm and a depth of 20-30 mm. Then we cut the "hairpin" with a wheel about 20 mm in. The "morels" are required to be completely removed or at least cut, creating a 30 x 30 x 40mm reverse wedge recess. Permanent Pool Sealing

We rinse the holes with plenty of water, on the one hand to remove the generated solids, on the other hand to saturate the area with water, which is a necessary condition for the operation of the penetrating, penetrating, sealing material with chemical action and crystal growth PENETRON® and the same technology repair PENECRETE MORTAR®. On a surface that is wet and without ponds of water, apply an aqueous mixture of PENETRON waterproofing material®, in a mixing ratio of 5 parts PENETRON powder® with 3.5 parts of water (by volume), only in the area of the holes and nests and 1 cm around them.

Permanent Pool Sealing

While the application of PENETRON type sealant® is still fresh, we mix PENECRETE MORTAR powder of chemical action and crystal growth repair mortar®, with enough water to achieve the texture we want, like plasticine [usual mixing ratio is 4.5 parts PENECRETE MORTAR® with 1 part of water (by volume)] and fill the holes and nests of the poor concreting. Once the repair mortar PENECRETE MORTAR® pulled, but still moist, followed by a second, local application only, with an aqueous mixture of PENETRON®.

-

Application of the endochemical sealant with crystal growth PENETRON®

It is possible to either apply PENETRON's water-based coating, penetrating, chemical action and crystal growth sealant® only on the inner surface of the pool, or also on the outer surface (after the surrounding surface has been excavated). Alternatively, the SEALCOAT system can be applied to the external surfaceTM FLEX (22.68 kg PENETRON® SEALCOAT in solution with 4 kg PENECRYLTM ELASTIC and 3 kg of water), reinforced with mesh or without or the application of the elastomeric polyurethane membrane, two components, PENECOAT™ HYPER ELASTIC BLACK, with a roller, brush or notched trowel, on the properly primed and prepared surface. Permanent Pool Waterproofing

This is followed by soaking for 1 – 2 days, to activate the PENETRON crystal growth system® and then 12 days of waiting for the system to fully activate. Afterwards, the pool is filled with cold clean water (for 3-4 days) and emptied, for the complete cleaning and control of the pool. Permanent Pool Sealing

-

Neutralization

Because the application of PENETRON products® on the surface of the concrete, they cause the creation and appearance of silicates, not only inside the concrete, but most of the time also on the application surface (usually after the first 48 hours), you create a technical issue by reducing the adhesion of decorative coatings or paints .

The problem is dealt with by the process called "neutralization". The neutralization is essentially a "washing" of the surface after about 3 weeks (safe time of the PENETRON system's operation®) with a low "aggressive" acid, such as a 3-8% hydrochloric acid (HCl) solution or a vinegar-water solution (in a ratio of 1:1 to 1:3, depending on the acidity). Permanent Pool Sealing

During application, after cleaning the surface with a broom, using a brush and a plastic container containing the neutralization liquid, we "wash" the surface and then, after a few minutes, rinse with plenty of clean water. The surface can then, after drying, be plastered or painted.

Alternatively, in the case of coatings or coating mortars, it can be applied within 48 hours and before the appearance of silicates on the surface. In this case, the time for overlay is minimized, however, the inability to control the correct application and operation of the system remains a disadvantage. Also, in this case, there is always a small chance that some percentage of crystals will penetrate the mortars or plasters and appear slightly on their surface. Permanent Pool Sealing

-

Applying a layer of adhesion and "mud" or mortar, to cover the concrete elements, to smooth the walls and bottom of the pool.

Initially, an adhesion layer is applied on the concrete elements for the application of the main cement mortar. The adhesion layer includes either the application of PENETRON acrylic resin® ACRYLIC BONDCRETETM or PRIMER STX 100™, depending on the substrate conditions, undiluted with an indicative consumption of 4.9 Lt/m2, or the application of adhesion material, "cast", which consists of 1 part cement with 2-3 parts sand (by volume) mixed in an aqueous solution of 1 part PENETRON acrylic resin® LATEX with two parts water (by volume).

Then the "guides" are made for the application of the filler or mortar. "Drivers" and "fill" consist of 1 part cement and 3 parts sand mixed in a solution of 1 part PENETRON building resin® LATEX with two to three parts water (by volume), to which polypropylene fibers are added to prevent cracking. The cement content of the leveling mortar and "guides" is 400-500 kg/m3. PENETRON ADMIX is also added® in a proportion of 0.8 – 1% by weight of cement. If the weight measurements are accurate, the consumption of 0.8% per weight of cement of PENETRON ADMIX® is a sufficient and safe amount. Permanent Pool Sealing

NOTE: In all previous applications lime is never used.

-

Finishing layer of cement mortar (fine or ground).

After the smoothing layer with cement mortar ("slurry"), there is usually a thin layer of mortar with fine aggregates and a very good finish. Especially in cases where pool painting follows (PENECOATTM POOL).

This thin finish layer can be produced with conventional materials such as fine sand and quartz aggregate and high cement content (>400 kg/m3). Alternatively, ready-made product with fine-grained quartz aggregates, PENETRON, can be applied® TOP FINISH FINE, with an indicative consumption of 1.6 kg/m2 per mm of thickness, usually in a gray or white shade. It is recommended to use an adhesion primer (PENETRON® ACRYLIC BONDCRETETM). Finally, PENECOAT polyurethane pool paint is usedTM POOL in the desired color, with an indicative consumption of 0.15 to 0.20 kgr/m2 per layer. It is applied in two or three layers.

-

Finishing the smoothing layer by gluing tiles.

After applying the smoothing layer, instead of using PENECOAT pool polyurethane paintTM POOL, tiling is possible. It is recommended to previously seal the surface of the cement mortar with SEALCOAT two-component elastic or flexible, dependingTM FLEX (flexible system with mixing 22.68 kg PENETRON® SEALCOAT in solution with 4 kg PENECRYLTM ELASTIC and 3 kg of water) or SEALCOATTM ELASTIC (elastic system with mixing 22.68 kg PENETRON® SEALCOAT with 12 kg PENECRYLTM ELASTIC), depending on the requirements of the project, i.e. small and large requirements for bridging capillary cracks. Permanent Pool Sealing

Apply an aqueous coat of the required SEALCOAT™ FLEX or SEALCOAT™ ELASTIC evenly with a short-bristled brush. The next day, apply a second coat perpendicular to the first. The required consumption of the SEALCOAT™ FLEX mixture ~ 2kg/m2, for a total of 2 coats of SEALCOAT™ ELASTIC is ~ 2.5kg/m2, for a total of 2 layers. It is also possible to reinforce SEALCOAT™ SYSTEMS with glass mesh (5x5 mm frame). In this case, place the glass mesh on the fresh first layer and completely cover the mesh with the second layer, the next day. The addition of glass mesh may increase the consumption of the mixture to about 3 kg/m2 total in both layers.

Usually if it is considered that the smoothing cement mortar does not present problems or cracks, the SEALCOAT system is appliedTM FLEX, for better adhesion of the glue to the surface or in special cases where it is necessary to bridge larger cracks on the surface of the mortar, the SEALCOAT system is appliedTM ELASTIC. For bonding tiles over SEALCOAT systemsTM SYSTEMS, a special type of FLEX glue is used for swimming pools.

-

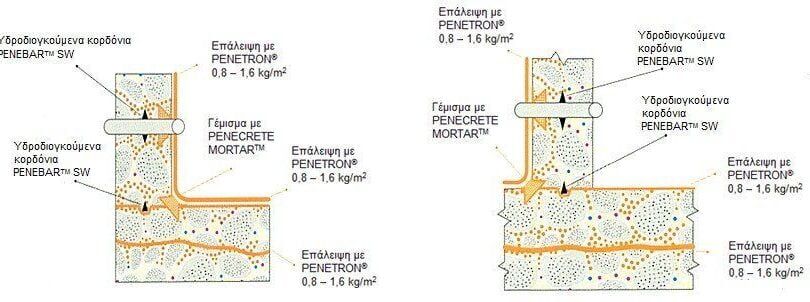

placement of a corresponding PENEBAR hydro-inflatable cord® SW in Pool Tubing & Fittings.

In the case of retrofitting components or piping that require perimeter sealing/sealing, the corresponding perimeter installation of PENEBAR water-inflatable cords is recommended® SW (recommended type of controlled swelling PENEBAR® SW 55 TYPE B or many times half of type 55 B). The material is placed at a depth of at least 5 cm and covered with PENEPLUG fast-setting hydraulic mortar with crystal growth®.

NOTE: The perimeter cavity for placing the hydro-inflatable cord to be filled, then with the PENEPLUG®, to be in the form of an inverted wedge, for better anchoring of the mortar.

II. Waterproofing – repair of failures of an existing pool, with tiles or mosaics on the final surface.

A. In case there are failures in the topping surface of the existing pool, with tiles or chippings, cracks and water loss, the tiles or chippings should be removed and the cracks should be repaired with repairing mortar.

1A. Removing the tiles or mosaics and checking the leveling cement mortar (healthy cement mortar).

First, the tiles are stripped or the paint is removed and the smoothing cement mortar is checked for any failures. If the leveling cement mortar is healthy, the surface is cleaned of friable or polluting factors, which can negatively affect the adhesion of the repair materials and wetting of the substrate as water saturation. Then either the repair mortar for general concrete repairs PENETRON is applied® MULTI PATCH, or the PENETRON modified polymer early strength development mortar® ACRYLIC PATCH, using PENETRON acrylic adhesion improver® ACRYLIC BONDCRETETM to stabilize the substrate and increase adhesion, where this is deemed necessary. The PENETRON® MULTI PATCH requires 3.1 kg to 3.4 kg of clean water per 25 kg of mortar and PENETRON® ACRYLIC PATCH requires 4.7 Lt to 5 Lt of clean water per 22.68 kg of mortar. For the repair of large cavities (greater than 50 mm fillings), add to PENETRON® ACRYLIC PATCH, granular aggregate, up to 1 cm. Permanent Pool Sealing

The percentage of aggregates we add must not exceed 25% by weight of PENETRON® ACRYLIC PATCH. For repairs subject to hydrostatic pressure and active leaks, PENETRON fast setting conventional repair mortar is applied® WATERPLUG RAPID. Immediately after mixing in the proper proportion, just the PENETRON® WATERPLUG RAPID acquires a plastic texture or a "claystone" texture, depending on the application, the material is applied forcefully to the point of repair, pressing it firmly by hand, with a trowel or with another flat object. Permanent Pool Sealing

Press firmly for over a minute. In case of heavy water flow, press for about 6 minutes. Remove excess material with a knife or any sharp object. Do not use a trowel or brush. The final surface of the repairs is finished with appropriate means, until a smooth surface is achieved.

2A. Waterproofing of the concrete surface with the conventional systems SEALCOATTM FLEX or SEALCOATTM ELASTIC

It is recommended to seal the surface of the cement mortar with SEALCOAT two-component elastic or flexible, dependingTM FLEX (flexible system with mixing 22.68 kg PENETRON® SEALCOAT in solution with 4 kg PENECRYLTM ELASTIC and 3 kg of water) or SEALCOATTM ELASTIC (elastic system with mixing 22.68 kg PENETRON® SEALCOAT with 12 kg PENECRYLTM ELASTIC), depending on the requirements of the project, i.e. small and large requirements for bridging capillary cracks. Apply an aqueous coat of the required SEALCOAT™ FLEX or SEALCOAT™ ELASTIC evenly with a short-bristled brush. Permanent Pool Sealing

The next day, apply a second coat perpendicular to the first. The required consumption of the SEALCOAT™ FLEX mixture ~ 2kg/m2, for a total of 2 coats of SEALCOAT™ ELASTIC is ~ 2.5kg/m2, for a total of 2 layers. It is also possible to reinforce SEALCOAT™ SYSTEMS with glass mesh (5x5 mm frame). In this case, place the glass mesh on the fresh first layer and completely cover the mesh with the second layer, the next day. The addition of glass mesh may increase the consumption of the mixture to about 3 kg/m2 total in both layers.

Usually if it is considered that the smoothing cement mortar does not present problems or cracks, the SEALCOAT system is appliedTM FLEX, for better adhesion of the glue to the surface or in special cases where it is necessary to bridge larger cracks on the surface of the mortar, the SEALCOAT system is appliedTM ELASTIC. For bonding tiles over SEALCOAT systemsTM SYSTEMS, a special type of FLEX glue is used for swimming pools.

B. In the case of an existing swimming pool with shaped end surfaces, with tiles or mosaics, where cracks, failures and water loss have been observed, where greater problems are observed on the surface of the cement mortar (detachments - cracks), then the removal of the tiles or mosaics is considered and removal of smoothing cement mortar and repair and sealing of sound concrete, using the PENETRON endochemical crystal growth system® on the concrete surface.

1B. Stripping the tiles and checking the leveling cement mortar (loose cement mortar).

First, the tiles or tesserae are stripped and the leveling cement mortar is checked for any failures. If the leveling cement mortar shows failures and its removal is deemed necessary, its removal is carried out using high pressure water jets (300 – 500 bar), until the healthy concrete is exposed. Permanent Pool Sealing

Then we treat water ingress from cracks with PENEPLUG active crystal growth quick setting mortar®, (mixed with a little water, form of gravel). To implement PENEPLUG®, we should widen the cracks with a digging tool to a width of 2-3 cm and with a conical base on the inside, for better anchoring of the tachypekt during its application. We deal with the stop joints in the same way, cutting on both sides with a cutting wheel and then creating a conical "gutter", about 3 cm wide, using a digging tool. Then, we apply the PENEPLUG quick-setting mortar®. Permanent Pool Sealing

In some cases, depending on the design of the works, we can apply PENEPLUG first®, so as to limit the inflow of water and then to carry out the treatment with water jetting, since the PENEPLUG® has acquired good mechanical strength. It must be clarified that PENEPLUG®, after drawing (still fresh), 1 – 2 coats of PENETRON water-based chemical action and crystal growth mixture should be applied to it®, in a mixing ratio of 5 parts PENETRON powder® with 3 – 3.5 parts of water (by volume), for easy application with a brush, and consumption in total for both 2 layers, approx. 1.5 kg/m2.

By mechanical means we widen the holes and nests that have resulted from concreting. Also, by mechanical means we widen the area around the "hairpins" to a width of at least 35 mm and a depth of 20-30 mm. Then we cut the "hairpin" with a wheel about 20 mm in. The "morels" are required to be completely removed or at least cut, creating a 30 x 30 x 40mm reverse wedge recess. Permanent Pool Sealing

We rinse the holes with plenty of water, on the one hand to remove the generated solids, on the other hand to saturate the area with water, which is a necessary condition for the operation of the penetrating, penetrating, sealing material with chemical action and crystal growth PENETRON® and the same technology repair PENECRETE MORTAR®. On a surface that is wet and without ponds of water, apply an aqueous mixture of PENETRON waterproofing material®, in a mixing ratio of 5 parts PENETRON powder® with 3.5 parts of water (by volume), only in the area of the holes and nests and 1 cm around them. Permanent Pool Sealing

While the application of PENETRON type sealant® is still fresh, we mix PENECRETE MORTAR powder of chemical action and crystal growth repair mortar®, with enough water to achieve the texture we want, like plasticine [usual mixing ratio is 4.5 parts PENECRETE MORTAR® with 1 part of water (by volume)] and fill the holes and nests of the poor concreting. Once the repair mortar PENECRETE MORTAR® pulled, but still moist, followed by a second, local application only, with an aqueous mixture of PENETRON®. Permanent Pool Sealing

2B. Application of the endochemical sealant with crystal growth PENETRON®

It is possible to either apply PENETRON's water-based coating, penetrating, chemical action and crystal growth sealant® only on the inner surface of the pool, or also on the outer surface (after the surrounding surface has been excavated). Alternatively, on the outer surface it is possible to apply the SEALC system

OATTM FLEX (22.68 kg PENETRON® SEALCOAT in solution with 4 kg PENECRYLTM ELASTIC and 3 kg of water), reinforced with mesh or without or the application of the elastomeric polyurethane membrane, two components, PENECOAT™ HYPER ELASTIC BLACK, with a roller, brush or notched trowel, on the properly primed and prepared surface. Permanent Pool Sealing

This is followed by soaking for 1 – 2 days, to activate the PENETRON crystal growth system® and then 12 days of waiting for the system to fully activate. Afterwards, the pool is filled with cold clean water (for 3-4 days) and emptied, for the complete cleaning and control of the pool. Permanent Pool Sealing

3B. Neutralization

Because the application of PENETRON products® on the surface of the concrete, they cause the creation and appearance of silicates, not only inside the concrete, but most of the time also on the application surface (usually after the first 48 hours), you create a technical issue by reducing the adhesion of decorative coatings or paints . The problem is dealt with by the process called "neutralization". The neutralization is essentially a "washing" of the surface after about 3 weeks (safe time of PENETRON system operation®) with a low "aggressive" acid, such as a 3-8% hydrochloric acid (HCl) solution or a vinegar-water solution (in a ratio of 1:1 to 1:3, depending on the acidity).

During the application, after the surface is cleaned with a vacuum cleaner, use a brush and a plastic pail, containing the solution for the neutralization, “wash” the surface with the solution and after a few minutes, wash the surface with excess water. Then, the surface, can be coated or painted, after it is dry. Alternatively, for the use of decorative screeds, they can be applied within the first 48 hours and before the formation of the silicic acids on the surface. In that case, the time for the coating application is minimized, but the drawback is the inability to control the correct application and operation of the system. Also, in that case, there is always a small possibility for a percent of the formed crystals to penetrate the coatings or screeds and appear on the surface.

4B. Applying a layer of adhesion and "mud" or mortar, to cover the concrete elements, to smooth the walls and bottom of the pool.

Initially, an adhesion layer is applied on the concrete elements for the application of the main cement mortar. The adhesion layer includes either the application of PENETRON acrylic resin® ACRYLIC BONDCRETETM or PRIMER STX 100™, depending on the substrate conditions, undiluted with an indicative consumption of 4.9 Lt/m2, or the application of adhesion material, "cast", which consists of 1 part cement with 2-3 parts sand (by volume) mixed in an aqueous solution of 1 part PENETRON acrylic resin® LATEX with two parts water (by volume).

Then the "guides" are made for the application of the filler or mortar. "Drivers" and "fill" consist of 1 part cement and 3 parts sand mixed in a solution of 1 part PENETRON building resin® LATEX with two to three parts water (by volume), to which polypropylene fibers are added to prevent cracking. The cement content of the leveling mortar and "guides" is 400-500 kg/m3. PENETRON ADMIX is also added® in a proportion of 0.8 – 1% by weight of cement. If the weight measurements are accurate, the consumption of 0.8% per weight of cement of PENETRON ADMIX® is a sufficient and safe amount.

NOTE: In all previous applications lime is never used.

5B. Finishing cementitious screed layer (fine or grater).

It is recommended to seal the surface of the cement mortar with SEALCOAT two-component elastic or flexible, dependingTM FLEX (flexible system with mixing 22.68 kg PENETRON® SEALCOAT in solution with 4 kg PENECRYLTM ELASTIC and 3 kg of water) or SEALCOATTM ELASTIC (elastic system with mixing 22.68 kg PENETRON® SEALCOAT with 12 kg PENECRYLTM ELASTIC), depending on the requirements of the project, i.e. small and large requirements for bridging capillary cracks. Apply an aqueous coat of the required SEALCOAT™ FLEX or SEALCOAT™ ELASTIC evenly with a short-bristled brush. The next day, apply a second coat perpendicular to the first. The required consumption of the SEALCOAT™ FLEX mixture ~ 2kg/m2, for a total of 2 coats of SEALCOAT™ ELASTIC is ~ 2.5kg/m2, for a total of 2 layers. It is also possible to reinforce SEALCOAT™ SYSTEMS with glass mesh (5x5 mm frame). In this case, place the glass mesh on the fresh first layer and completely cover the mesh with the second layer, the next day. The addition of glass mesh may increase the consumption of the mixture to about 3 kg/m2 total in both layers.

Usually if it is considered that the smoothing cement mortar does not present problems or cracks, the SEALCOAT system is appliedTM FLEX, for better adhesion of the glue to the surface or in special cases where it is necessary to bridge larger cracks on the surface of the mortar, it is applied

Placement of corresponding PENEBAR hydro-inflatable cord® SW in Pool Tubing & Fittings.

In the case of retrofitting components or piping that require perimeter sealing/sealing, the corresponding perimeter installation of PENEBAR water-inflatable cords is recommended® SW (recommended type of controlled swelling PENEBAR® SW 55 TYPE B or many times half of type 55 B). The material is placed at a depth of at least 5 cm and covered with PENEPLUG fast-setting hydraulic mortar with crystal growth®.

NOTE: The perimeter cavity for placing the hydro-inflatable cord to be filled, then with the PENEPLUG®, to be in the form of an inverted wedge, for better anchoring of the mortar.

III. Waterproofing – repair of existing pool failures, with pool paint on the finished surface.

A. In case there are failures in the topping surface of the existing pool with tiles or chippings and there are cracks and water loss, the tiles or chippings should be removed and the cracks should be repaired, with repairing mortar.

1A. Removal of paint and control of leveling cement mortar (healthy cement mortar).

First, the paint is removed and the smoothing cement mortar is checked for any failures. If the leveling cement mortar is healthy, the surface is cleaned of friable or polluting factors, which can negatively affect the adhesion of the repair materials and wetting of the substrate as water saturation. Then either the repair mortar for general concrete repairs PENETRON is applied® MULTI PATCH, or the PENETRON modified polymer early strength development mortar® ACRYLIC PATCH, using PENETRON acrylic adhesion improver® ACRYLIC BONDCRETETM to stabilize the substrate and increase adhesion, where this is deemed necessary. The PENETRON® MULTI PATCH requires 3.1 kg to 3.4 kg of clean water per 25 kg of mortar and PENETRON® ACRYLIC PATCH requires 4.7 Lt to 5 Lt of clean water per 22.68 kg of mortar. For the repair of large cavities (greater than 50 mm fillings), add to PENETRON® ACRYLIC PATCH, granular aggregate, up to 1 cm. The percentage of aggregates we add must not exceed 25% by weight of PENETRON® ACRYLIC PATCH. For repairs subject to hydrostatic pressure and active leaks, PENETRON fast setting conventional repair mortar is applied® WATERPLUG RAPID. Immediately after mixing in the proper proportion, just the PENETRON® WATERPLUG RAPID acquires a plastic texture or a "claystone" texture, depending on the application, the material is applied forcefully to the point of repair, pressing it firmly by hand, trowel or other flat object. Press firmly for over a minute. In case of heavy water flow, press for about 6 minutes. Remove excess material with a knife or any sharp object. Do not use a trowel or brush. The final surface of the repairs is finished with suitable means, until a smooth surface is achieved.

2A. Waterproofing of the concrete surface with the conventional systems SEALCOATTM FLEX or SEALCOATTM ELASTIC.

After the smoothing layer with cement mortar ("slurry"), there is usually a thin layer of mortar with fine aggregates and a very good finish. Especially in cases where pool painting follows (PENECOATTM POOL).

This thin finish layer can be produced with conventional materials such as fine sand and quartz aggregate and high cement content (>400 kg/m3). Alternatively, ready-made product with fine-grained quartz aggregates, PENETRON, can be applied® TOP FINISH FINE, with an indicative consumption of 1.6 kg/m2 per mm of thickness, usually in a gray or white shade. It is recommended to use an adhesion primer (PENETRON® ACRYLIC BONDCRETETM). Finally, PENECOAT polyurethane pool paint is usedTM POOL in the desired color, with an indicative consumption of 0.15 to 0.20 kgr/m2 per layer. It is applied in two or three layers.

B. In the case of an existing pool with shaped end surfaces, with pool paint, where cracks and water loss have been observed, where major problems are observed on the surface of the cement mortar (detachment - cracks), then the removal of the tiles or mosaics and removal of the cement mortar is considered smoothing and repair and sealing of sound concrete, using the PENETRON endochemical action system with crystal growth® on the concrete surface.

1B. Removal of paint and control of leveling cement mortar (loose cement mortar).

First of all, remove colors and check of cementitious screed layer for failures. If the cementitious screed layer is not healthy, then the dismantling of cementitious screed layer is required, by a high-pressure jet waterblasting (300- 500 bar). Depending on the working procedures, concrete surface can be treated and cleaned by a high-pressure jet waterblasting (300-500 bar), for better visual contact with faulty areas.

Then we treat water ingress from cracks with PENEPLUG active crystal growth quick setting mortar®, (mixed with a little water, form of gravel). To implement PENEPLUG®, we should widen the cracks with a digging tool to a width of 2-3 cm and with a conical base on the inside, for better anchoring of the tachypekt during its application. We deal with the stop joints in the same way, cutting on both sides with a cutting wheel and then creating a conical "gutter", about 3 cm wide, using a digging tool. Then, we apply the PENEPLUG quick-setting mortar®.

In some cases, depending on the design of the works, we can apply PENEPLUG first®, so as to limit the inflow of water and then to carry out the treatment with water jetting, since the PENEPLUG® has acquired good mechanical strength. It must be clarified that PENEPLUG®, after drawing (still fresh), 1 – 2 coats of PENETRON water-based chemical action and crystal growth mixture should be applied to it®, in a mixing ratio of 5 parts PENETRON powder® with 3 – 3.5 parts of water (by volume), for easy application with a brush, and consumption in total for both 2 layers, approx. 1.5 kg/m2.

By mechanical means we widen the holes and nests that have resulted from concreting. Also, by mechanical means we widen the area around the "hairpins" to a width of at least 35 mm and a depth of 20-30 mm. Then we cut the "hairpin" with a wheel about 20 mm in. The "morels" are required to be completely removed or at least cut, creating a 30 x 30 x 40mm reverse wedge recess. We rinse the holes with plenty of water, on the one hand to remove the generated solids, on the other hand to saturate the area with water, which is a necessary condition for the operation of the penetrating, penetrating, sealing material with chemical action and crystal growth PENETRON® and the same technology repair PENECRETE MORTAR®. On a surface that is wet and without ponds of water, apply an aqueous mixture of PENETRON waterproofing material®, in a mixing ratio of 5 parts PENETRON powder® with 3.5 parts of water (by volume), only in the area of the holes and nests and 1 cm around them. While the application of PENETRON type sealant® is still fresh, we mix PENECRETE MORTAR powder of chemical action and crystal growth repair mortar®, with enough water to achieve the texture we want, like plasticine [usual mixing ratio is 4.5 parts PENECRETE MORTAR® with 1 part of water (by volume)] and fill the holes and nests of the poor concreting. Once the repair mortar PENECRETE MORTAR® pulled, but still moist, followed by a second, local application only, with an aqueous mixture of PENETRON®.

2B. Application of the endochemical sealant with crystal growth PENETRON®

It is possible to either apply PENETRON's water-based coating, penetrating, chemical action and crystal growth sealant® only on the inner surface of the pool, or also on the outer surface (after the surrounding surface has been excavated). Alternatively, the SEALCOAT system can be applied to the external surfaceTM FLEX (22.68 kg PENETRON® SEALCOAT in solution with 4 kg PENECRYLTM ELASTIC and 3 kg of water), reinforced with mesh or without or the application of the elastomeric polyurethane membrane, two components, PENECOAT™ HYPER ELASTIC BLACK, with a roller, brush or notched trowel, on the properly primed and prepared surface.

This is followed by soaking for 1 – 2 days, to activate the PENETRON crystal growth system® and then 12 days of waiting for the system to fully activate. Then, the pool is filled with cold clean water (for 3-4 days) and emptied, for the complete cleaning and control of the pool.

3B. Neutralization

Because the application of PENETRON products® on the surface of the concrete, they cause the creation and appearance of silicates, not only inside the concrete, but most of the time also on the application surface (usually after the first 48 hours), you create a technical issue by reducing the adhesion of decorative coatings or paints . The problem is dealt with by the process called "neutralization". The neutralization is essentially a "washing" of the surface after about 3 weeks (safe time of PENETRON system operation®) with a low "aggressive" acid, such as a 3-8% hydrochloric acid (HCl) solution or a vinegar-water solution (in a ratio of 1:1 to 1:3, depending on the acidity).

During the application, after the surface is cleaned with a vacuum cleaner, use a brush and a plastic pail, containing the solution for the neutralization, “wash” the surface with the solution and after a few minutes, wash the surface with excess water. Then, the surface, can be coated or painted, after it is dry. Alternatively, for the use of decorative screeds, they can be applied within the first 48 hours and before the formation of the silicic acids on the surface. In that case, the time for the coating application is minimized, but the drawback is the inability to control the correct application and operation of the system. Also, in that case, there is always a small possibility for a percent of the formed crystals to penetrate the coatings or screeds and appear on the surface.

4B. Applying a layer of adhesion and "mud" or mortar, to cover the concrete elements, to smooth the walls and bottom of the pool.

Initially, an adhesion layer is applied on the concrete elements for the application of the main cement mortar. The adhesion layer includes either the application of PENETRON acrylic resin® ACRYLIC BONDCRETETM or PRIMER STX 100™, depending on the substrate conditions, undiluted with an indicative consumption of 4.9 Lt/m2, or the application of adhesion material, "cast", which consists of 1 part cement with 2-3 parts sand (by volume) mixed in an aqueous solution of 1 part PENETRON acrylic resin® LATEX with two parts water (by volume).

Then the "guides" are made for the application of the filler or mortar. "Drivers" and "fill" consist of 1 part cement and 3 parts sand mixed in a solution of 1 part PENETRON building resin® LATEX with two to three parts water (by volume), to which polypropylene fibers are added to prevent cracking. The cement content of the leveling mortar and "guides" is 400-500 kg/m3. PENETRON ADMIX is also added® in a proportion of 0.8 – 1% by weight of cement. If the weight measurements are accurate, the consumption of 0.8% per weight of cement of PENETRON ADMIX® is a sufficient and safe amount.

NOTE: In all previous applications lime is never used.

5B. Finishing cementitious screed layer (fine or grater).

After the smoothing layer with cement mortar ("slurry"), there is usually a thin layer of mortar with fine aggregates and a very good finish. Especially in cases where pool painting follows (PENECOATTM POOL).

This thin finish layer can be produced with conventional materials such as fine sand and quartz aggregate and high cement content (>400 kg/m3). Alternatively, ready-made product with fine-grained quartz aggregates, PENETRON, can be applied® TOP FINISH FINE, with an indicative consumption of 1.6 kg/m2 per mm of thickness, usually in a gray or white shade. It is recommended to use an adhesion primer (PENETRON® ACRYLIC BONDCRETETM). Finally, PENECOAT polyurethane pool paint is usedTM POOL in the desired color, with an indicative consumption of 0.15 to 0.20 kgr/m2 per layer. It is applied in two or three layers.

C. In the case of an existing swimming pool with shaped end surfaces, with swimming pool paint, where a failure of the paint has been observed, without the creation of failures in the construction, then repainting the pool with polyurethane paint is considered PENECOATTM POOL.

First, the paint color is rubbed well until it is well polished. Any loose or friable parts or dirt that can adversely affect the adhesion of the new paint must be removed. Old paint coatings must be removed and the surface roughened for better paint adhesion. In the event of cracks appearing on the surface of the cement mortar, either the repair mortar for general concrete repairs PENETRON is applied® MULTI PATCH, or the PENETRON modified polymer early strength development mortar® ACRYLIC PATCH, using PENETRON acrylic adhesion improver® ACRYLIC BONDCRETETM to stabilize the substrate and increase adhesion, where this is deemed necessary. The PENETRON® MULTI PATCH requires 3.1 kg to 3.4 kg of clean water per 25 kg of mortar and PENETRON® ACRYLIC PATCH requires 4.7 Lt to 5 Lt of clean water per 22.68 kg of mortar. For the repair of large cavities (greater than 50 mm fillings), add to PENETRON® ACRYLIC PATCH, granular aggregate, up to 1 cm. The percentage of aggregates we add must not exceed 25% by weight of PENETRON® ACRYLIC PATCH.

Finally, and as long as the surface humidity is less than 5%, PENECOAT polyurethane pool paint is appliedTM POOL in the desired color, with an indicative consumption of 0.15 to 0.20 kgr/m2 per layer. It is applied in two or three layers.

Placement of corresponding PENEBAR hydro-inflatable cord® SW in Pool Tubing & Fittings.

In the case of retrofitting components or piping that require perimeter sealing/sealing, the corresponding perimeter installation of PENEBAR water-inflatable cords is recommended® SW (recommended type of controlled swelling PENEBAR® SW 55 TYPE B or many times half of type 55 B). The material is placed at a depth of at least 5 cm and covered with PENEPLUG fast-setting hydraulic mortar with crystal growth®.

NOTE: The perimeter cavity for placing the hydro-inflatable cord to be filled, then with the PENEPLUG®, to be in the form of an inverted wedge, for better anchoring of the mortar.

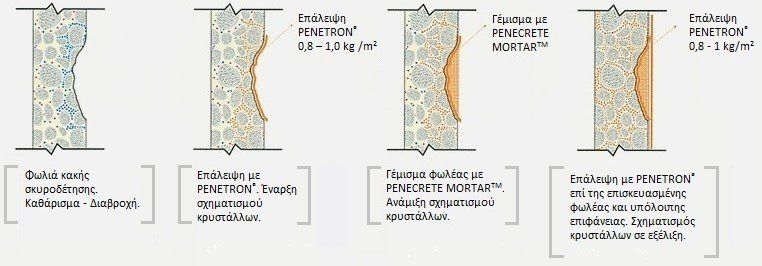

Following is a schematic illustration of discontinuity repairs with PENETRON chemical action and crystal growth materials® of PENETRON INTERNATIONAL LTD.

|

To clarify that the above is not a construction study, but a technical proposal according to the information we have for the corresponding project and based on our best experience and knowledge so far. For more information regarding safe use, the processing and storage of the products contact PENETRON HELLAS, at Product Characteristics Sheet and to Product Safe Use Leaflet for every product you use.

No Comments